Recycle Repurpose Reuse

OUO WHEELCHAIR

OUO Wheelchair

A wheelchair that is designed to use 90% of material recycled from broken share bikes. To reduce the environmental impact and bring job opportunities for locals.

2019 14 weeks school project

-

Introduction of project background. why ofo bikes? what happened to ofo?

-

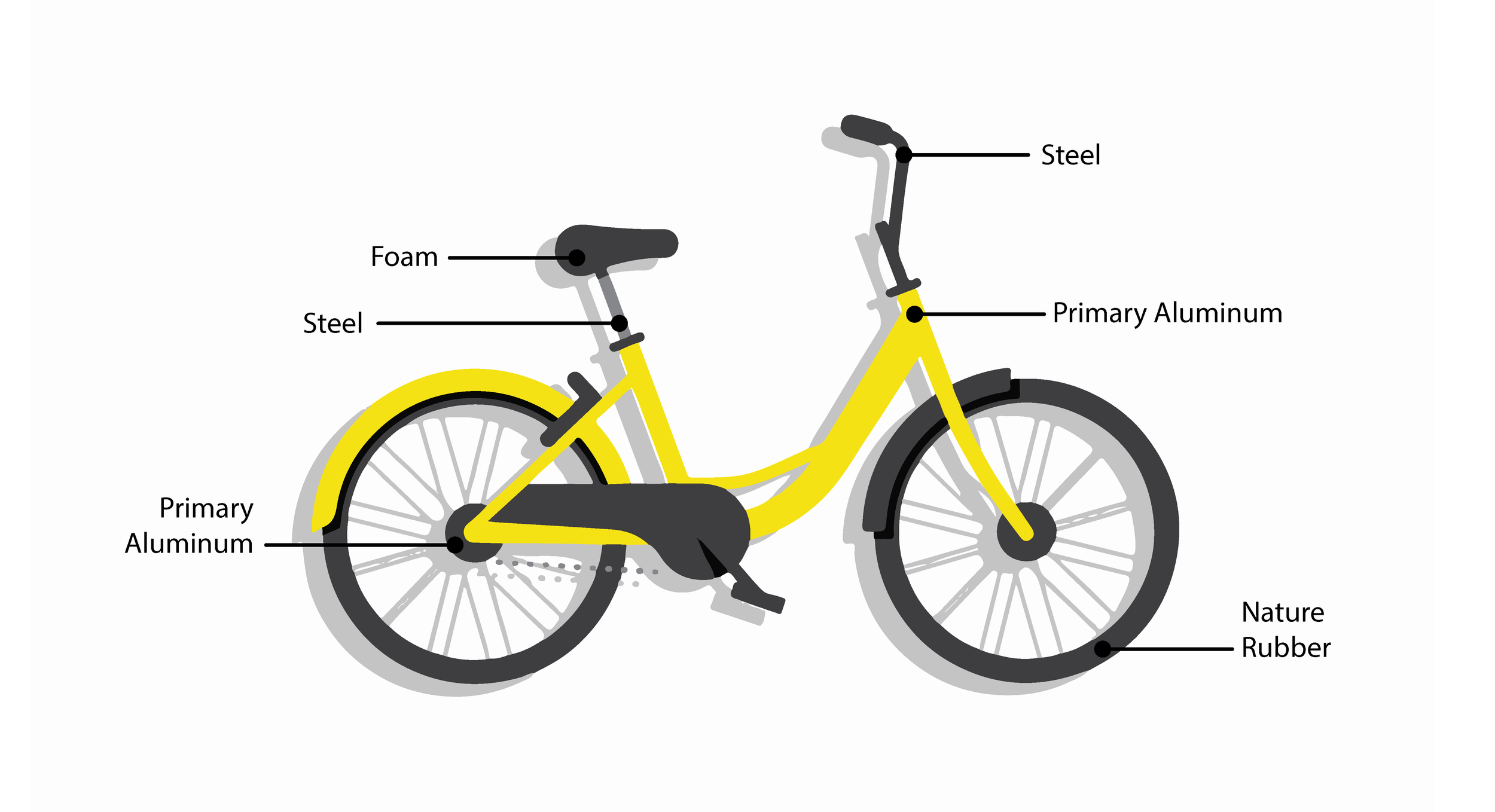

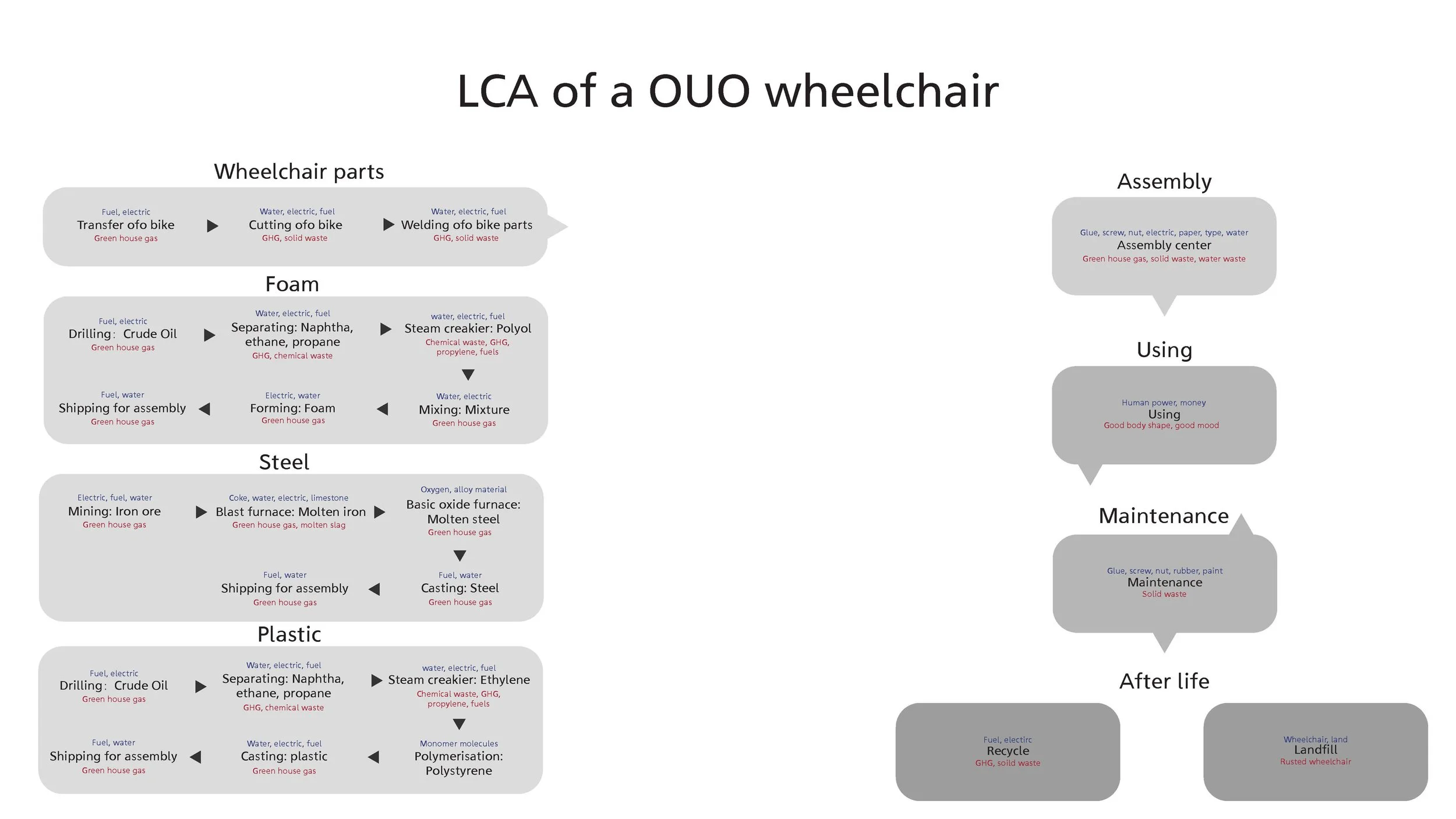

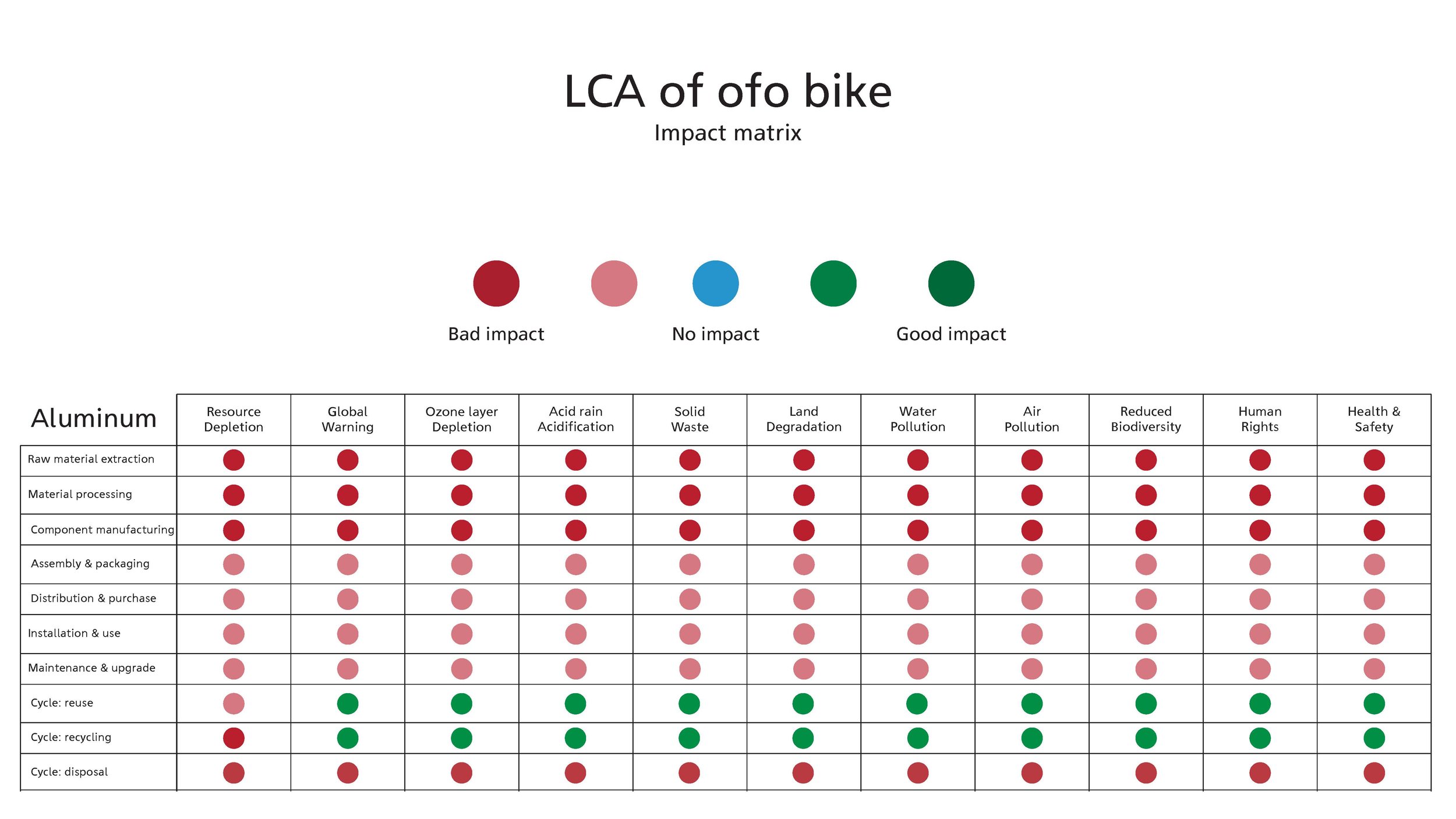

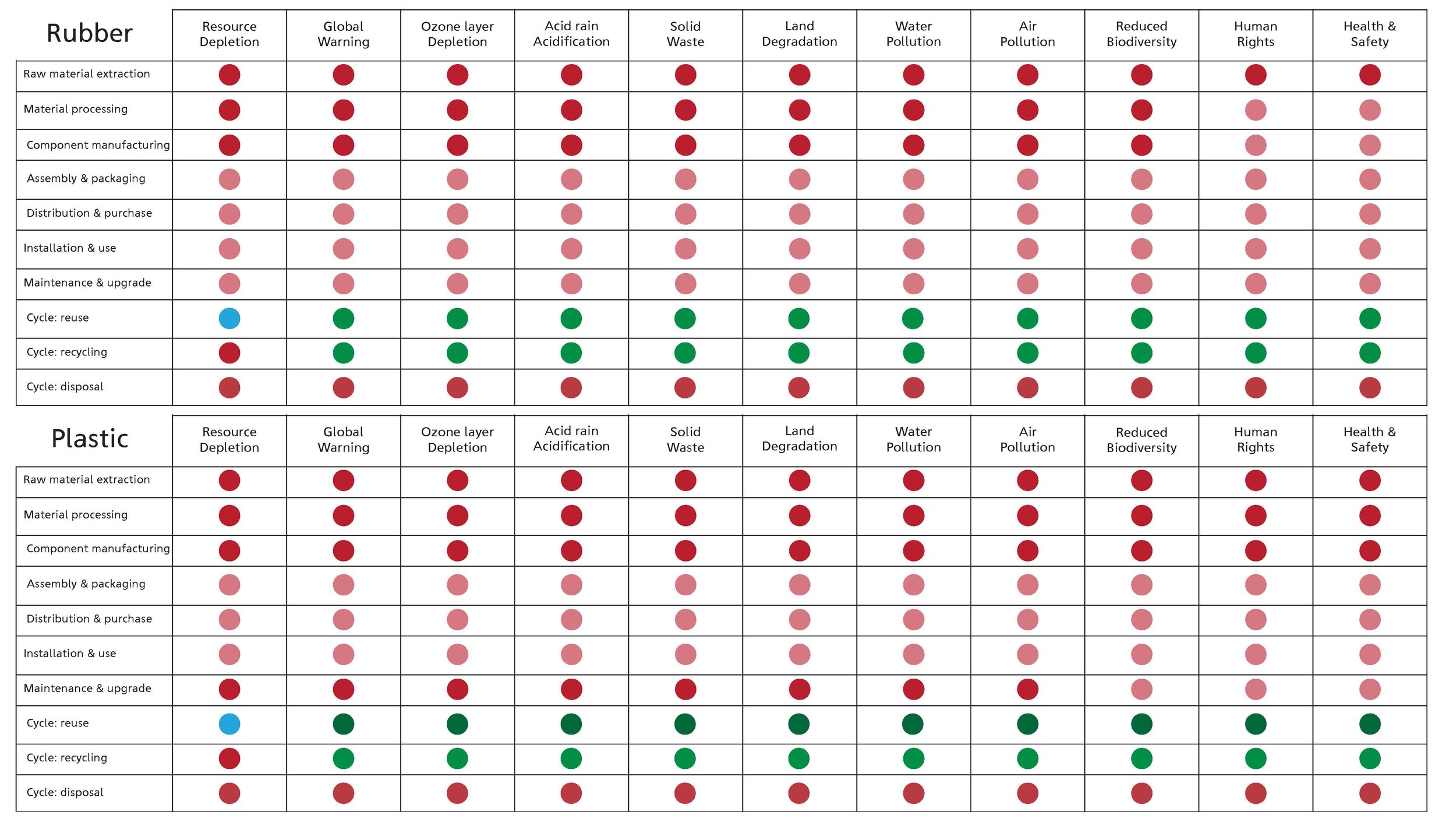

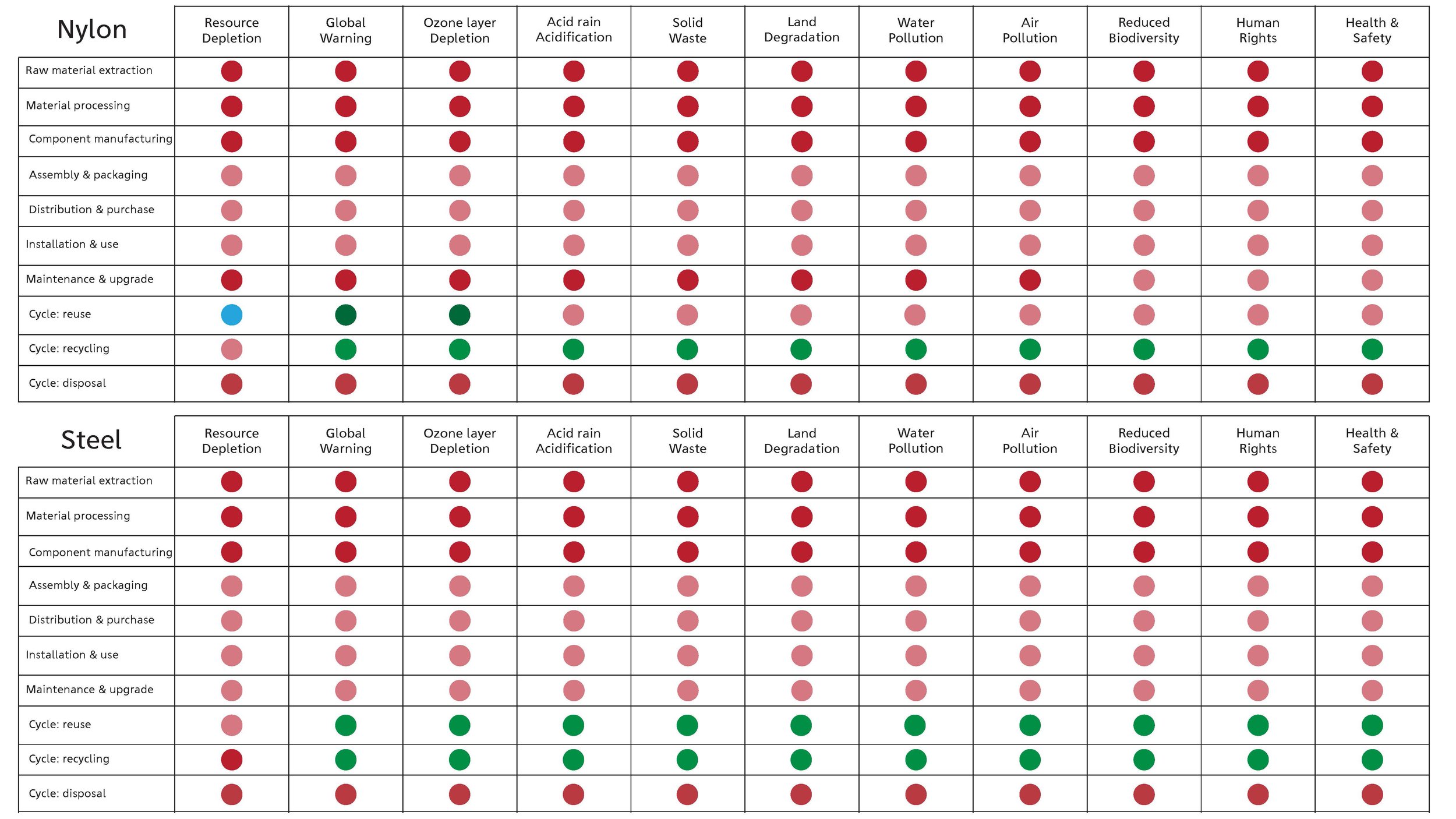

In order to start designing for ofo bikes, it is important to understand how it’s been made and whats the environmental impact is.

-

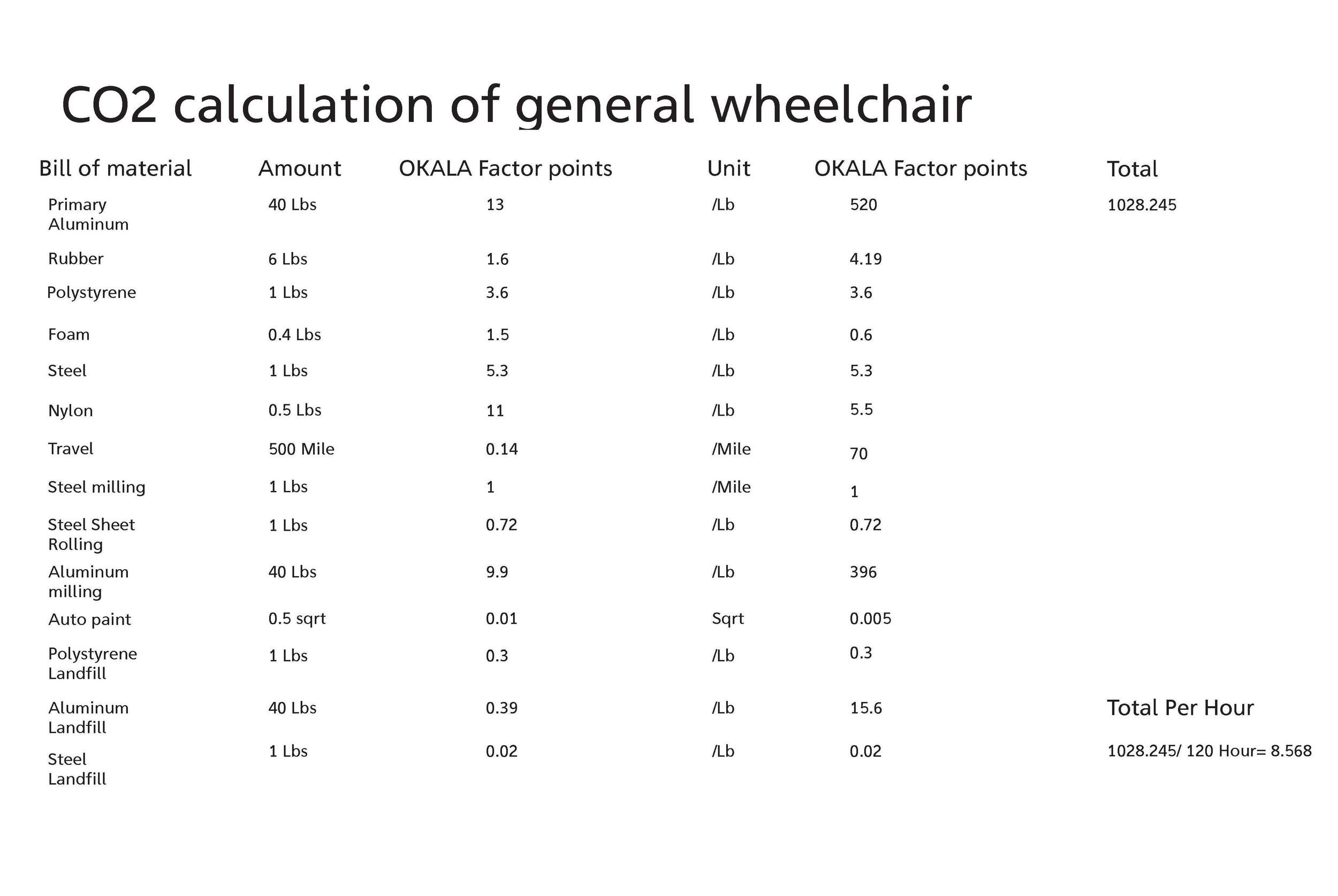

Based on LCA study of ofo bikes, setting up design goals for the projects.

-

To figure out the best use for the ofo bikes.

-

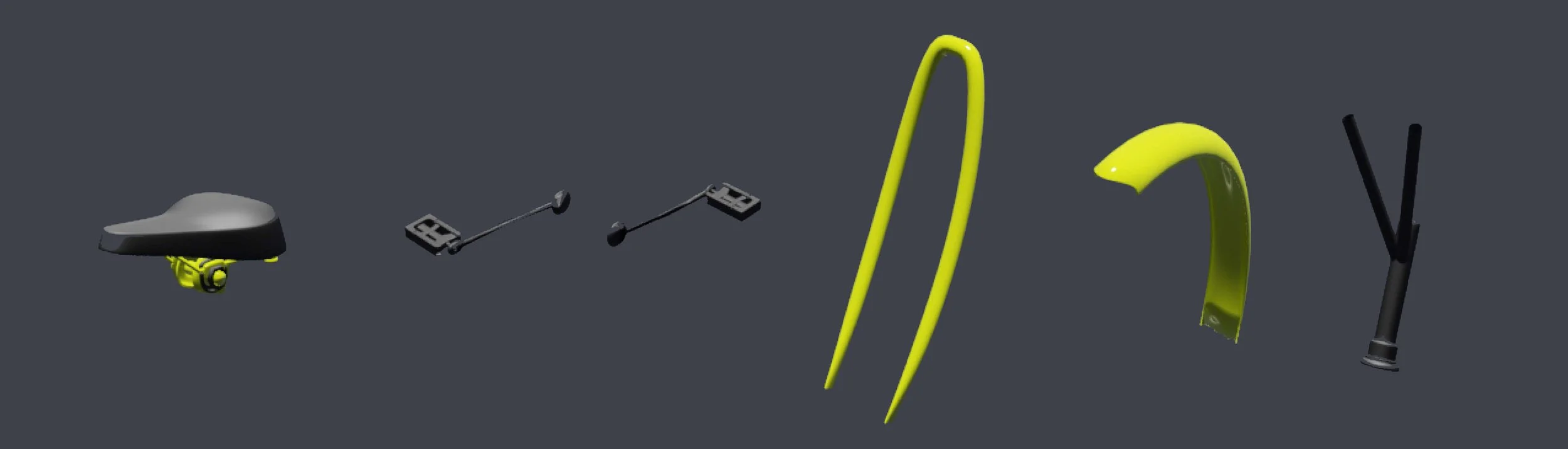

Details of how OUO wheelchair serves functions of wheelchair and how parts from ofo bike are used in OUO wheelchair.

-

What design goal was reached and not, and what is being left?

What is ofo?

ofo was the largest bike-sharing company in 2016; due to their excessive expansion and policy change, it faded out of the market in 2018. ofo left with over 10 million bicycles, and over 20% are damaged. Those bikes are a waste of resources and encroach on public space.

01.

Study on LCA of ofo bike

02.

The ofo bike is constructed with five materials: Foam, Steel, Primary Aluminum, Nature rubber, and Plastic. The LCA study starts from the beginning of the material to the end of service life, fully understanding the life cycle of one ofo the bikes to find design opportunities.

life cycle assessment

03.

Design Goals

A bicycle is a system in which any part fails, which may lead to the inability to use it. From the perspective of labor costs, building a new bicycle is cheaper than maintaining a damaged one. As a result, the average life of each bicycle is only three months, and most parts are new when they are abandoned.

Reduce Green House Gas emissions in the manufacturing process

Reduce transportation impact in material manufacture and distribution

Reduce the environmental impact of abandoned bikes

Benefit local community

Provide people who work for manufacturing a better and cleaner evinvorment

- Design for behavior change

- Reduce material use

- Replace material

- Single material

- Design for behavior change

- Replace material

- Single material

- Localize manufacture

- Design for behavior change

- Repurpose

- Producer takes back

- Design for product life pass change

- Build community

- Repurpose, Recycle

- Producer takes back

- Single material / Replace material

- Build community

- Repurpose, Recycle

- Single material

- Add on

04.

IDeation

The parts from bikes are perfect for making a wheelchair. Also, according to the Free Wheelchair Mission, there are 75 million people in need of a wheelchair who cannot afford one.

The wheelchair design picked is based on utilizing the main support structure of ofo bike as the main support structure for the wheelchair.

05.

Final Design

OUO Wheelchair

06.

Design Goals check & Reflections

Reduce Green House Gas emissions in the manufacturing process

Reduce transportation impact in material manufacture and distribution

Reduce the environmental impact of abandoned bikes

Benefit local community

Provide people who work for manufacturing a better and cleaner evinvorment

The OUO wheelchair is designed to reuse the material from ofo bikes. The wheelchair will not change the manufacturing process of the bike but will change the process of wheelchairs.

By setting the workshop nearby where ofo bikes are bing abandoned. It will decrease a lot of transportation from material to manufacture.

Using the material from ofo bikes reduces the number of abandoned ofo bikes.

Setting the workshop nearby where ofo bikes are being abandoned (Mainly in rural areas) will create job opportunities for locals.

Setting the workshop nearby where ofo bikes are being abandoned (Mainly in rural areas), People are closer to their homes and work with machine simple to use.

When using ofo bike as material for building the OUO wheelchair, a large amount of the raw material and processing are saved. Compared with building a new wheelchair from scratch, OUO wheelchair saved over 84% of CO2 emissions in the process.

During the process of making one OUO wheelchair, there are still some leftover parts from ofo bikes. During the manufacturing process, those parts will be cleaned and taken apart. The leftover parts are ready for recycling in the end.

Flat packaging enables OUO wheelchair to ship anywhere needed. At the same time, the local shop can utilize local materials to make seat cushions and add-on pieces.